Starter Kit Elektrospinning/Dönüştürme Ekipmanı

The Starter Kit electrospinning system is designed for low-cost, small-scale nanofiber research, producing results from a single-nozzle configuration in a compact unit.

NS + NanoSpinner Plus Elektrospinning/Püskürtme Ekipmanları

The NS Plus is an ideal solution for lower-budget projects working on small-scale nanofibers research...

NE100 Elektrospinning/Püskürtme Makinesi

The NE100 Electrospinning Unit, a model in between basic and advanced levels, all process parameters can be edited from its touch screen panel...

NE200 Elektrospinning/Püskürtme Makinesi

NE200 lab scale electrospinning units are the basic electrospinning units for the...

NE300 Çok Nozüllü Elektrospinning/Püskürtme Makinesi

NE300 Laboratory scale electrospinning unit which provides the possibility to produce larger area uniform nanofiber coating, is suitable for advanced...

Nanospinner24 Çok Nozüllü Elektrospinning/Püskürtme Makinesi

Nanospinner 24 electrospinning equipment was designed to develop sample nanofiber membranes used in primarily...

PE-550 Elektrospinning Makinesi/Püskürtme

Nanospinner Pilot Line Semi Industrial Electrospinning Machine is designed for precise product development processes. The model is specifically...

Nanospinner 416 Endüstriyel Elektrospinning/Püskürtme

NANOSPINNER416 is an electrospinning oriented industrial nanofiber production machine that can coat 1 meter width fabrics with 50-400 nm (0.05-0.4 μm)

PE-300 Elektrospinning/Püskürtme Makinesi

Nanospinner Pilot Line Semi Industrial Electrospinning Machine is designed for precise product development processes. The model is specifically...

NS1 NanoSpinner Elektrospinning/Püskürtme Ekipmanı

The NS1 model includes all the basic components required for electrospinning operations: syringe pump, high voltage power supply, and collector parts.

NS1 NanoSpinner Electrospinning/Spraying Equipment

The NS1 model includes all the basic components required for electrospinning operations: syringe pump, high voltage power supply, and collector parts.

PE-300 Electrospinning/Spraying Machine

Nanospinner Pilot Line Semi Industrial Electrospinning Machine is designed for precise product development processes. The model is specifically...

Nanospinner 416 Industrial Electrospinning/Spraying

NANOSPINNER416 is an electrospinning oriented industrial nanofiber production machine that can coat 1 meter width fabrics with 50-400 nm (0.05-0.4 μm)

Nanospinner24 Multinozzle Electrospinning/Spraying Machine

Nanospinner 24 electrospinning equipment was designed to develop sample nanofiber membranes used in primarily...

NE300 Multinozzle Electrospinning/Spraying Machine

NE300 Laboratory scale electrospinning unit which provides the possibility to produce larger area uniform nanofiber coating, is suitable for advanced...

NE200 Electrospinning/Spraying Machine

NE200 lab scale electrospinning units are the basic electrospinning units for the...

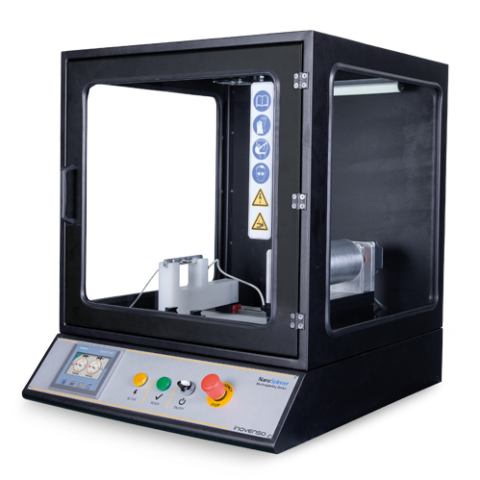

NE100 Electrospinning/Spraying Machine

The NE100 Electrospinning Unit, a model in between basic and advanced levels, all process parameters can be edited from its touch screen panel...

NS + NanoSpinner Plus Electrospinning/Spraying Equipment

The NS Plus is an ideal solution for lower-budget projects working on small-scale nanofibers research...

Starter Kit Electrospinning Equipment

The Starter Kit electrospinning system is designed for low-cost, small-scale nanofiber research, producing results from a single-nozzle configuration in a compact unit.

Starter Kit Electrospinning/Spinning Equipment

The Starter Kit electrospinning system is designed for low-cost, small-scale nanofiber research, producing results from a single-nozzle configuration in a compact unit.