Breathable waterproof fabrics

Waleed Mustafa

Clothing and wearables have been revolutionized in the current health and fitness conscious milieu. People are ready to spend their resources to get a highly efficient, well-toned body working at higher cardiac rates without any dangerous effects to the organs such as lungs. This is translated in activities such as running, hiking, and other sporting activities that require higher oxygen intake without letting the clothes soak water and get heavier in case of rain, snow, wind from the outside or excessive sweating from the inside. Evidence of these trends is found on social media platforms where an ever-increasing interest in fitness related content and education is seen in people of all ages. Other applications of these breathable waterproof fabrics are professional apparel such as in clean rooms, military, firemen and farming cloth wear. In medical usage, this technology can be transformed into wearables such as surgical garments, dressings, and hygiene products. The application for this technology is potentially innumerable.

To ensure this, fabric industries have upped their technology by providing light weight, breathable fabrics that are also waterproof and allow the person to perform physical activity more comfortably for longer periods without need to change their clothing. These include products from brands such as Gore-Tex®, The North Face®, Sympatex® etc.

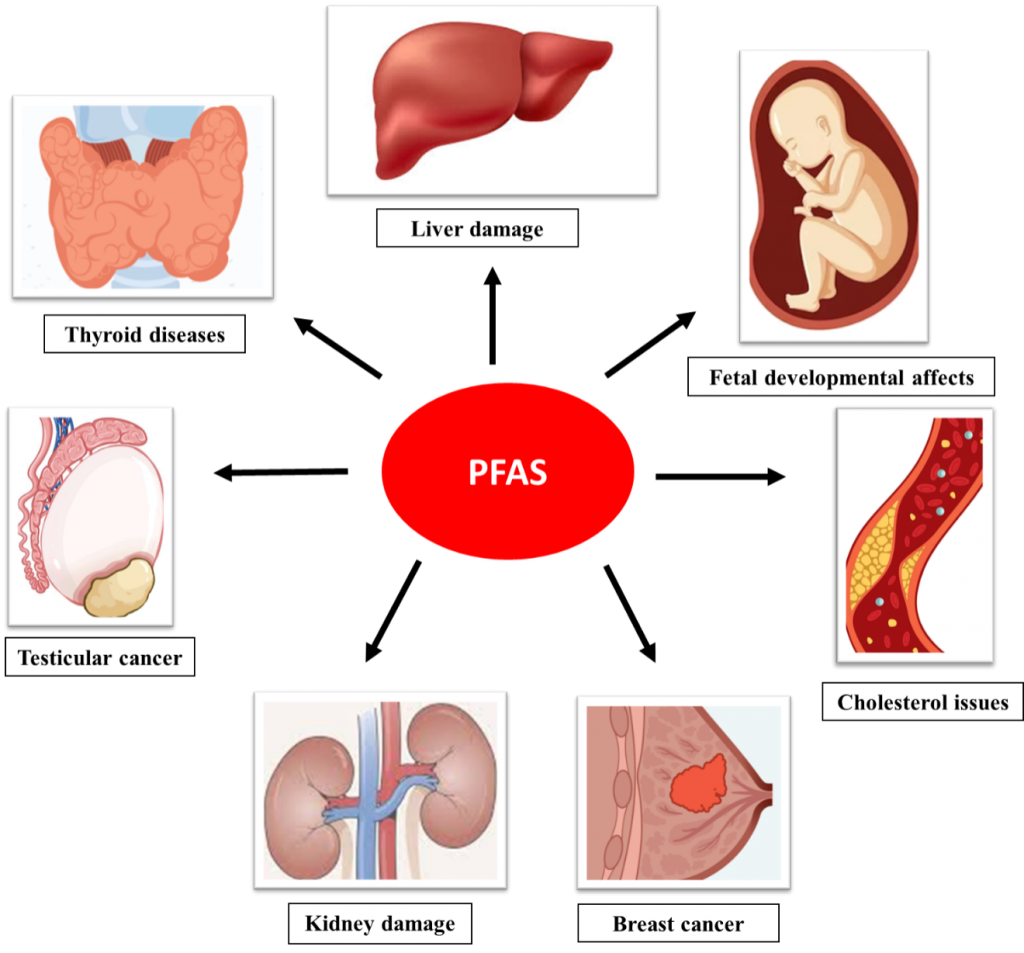

Among the many developed materials for these wearables and textiles, the per fluoroalkyl substances (PFAS) have been used extensively and tend to accumulate within the environment and human body. The presence of these PFAS pollutants as highlighted by environmental organizations including United Nations [1], OECD [2], HBM4EU [3], EEA [4] and in literature [5], is worrisome for all communities and their detrimental effects are summarized in Fig. 1.

Figure 1. Effects of Perfluoroalkyl substances on human body [4,5]

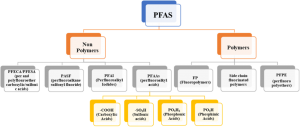

Multiple variants of PFAS exist and are said to be more than 5000 types and can be categorized generally as shown in Fig. 2. These chemicals are introduced into the environment and human body via many pathways such as during production, use and disposal. Due to their highly stable nature, they inhabit the indefinitely in water sources, sea, and soil habitats thus contaminating both animal and plant life [5]. Since they are non-degradable and cannot be naturally removed, they are popular as “forever chemicals”.

Figure 2. PFAS and their classifications [5]

A short summary of the details about formation of fabrics, important factors involved, and one of the technologies to make these fabrics is provided below.

Formation and working mechanics: Currently, there are three ways to make a breathable waterproof fabric which includes using high density woven fabrics, coated fabrics, and laminated fabrics. This article focuses mainly on laminated fabrics as they can provide both features comprehensively than the first two techniques of formation. An overview of fabric construction has been provided in Figure 1. which demonstrates the laminated three-layered scheme as an example to build breathable and waterproof fabric. This includes a layer of liner fabric which is in complete contact to the porous/fibrous membrane that acts as a barrier for larger molecules (vapors) and allows smaller molecules to pass through (air). The liner fabric acts as an inside garment and allows for the small sized/aerated vapors to reach the membrane interface while the athlete is sweating. The porous structure of the membrane then allows particles to penetrate through based on size while. Finally, the third layer of waterproof fabric hinders any water vapors passing through from the outside such as in form of rain, snow, or wind and lets the vapors from the inside permeate through and leave the fabric. A few important parameters considered in formation of these fabrics are material hydrophilicity/hydrophobicity, permeability, porosity, mechanical strength, resistance to temperature, and finally, attachment/lamination of each layer to one another.

Figure 3. Scheme of a three-layered breathable waterproof fabric.

Breathability: Breathability in fabrics is the ability of water vapors to successfully permeate through that fabric via diffusion and henceforth, facilitate cooling via evaporation [6]. Higher breathability means higher perspiration allowed from the skin to the outside of the fabric which helps in preventing moisture accumulation inside the fabric and ensures comfort for the wearer.

Breathability can be measured by using moisture vapor transmission rate which indicates the rate at which vapors are able to permeate through a meter square of fabric in 24 hours which gives a value in g/m2/day. Type of applications for the fabric are determined by the rating of breathability e.g., 5000 g/m2/day which is low breathability level might be suitable for fishing but for mountaineering, over 20000 g/m2/day is a must which means very high breathability level is required.

Waterproofness: Waterproofness is the ability of the fabric to disallow water to penetrate through the fabric. This means that the fabric must have such porosity that it cannot allow water in the form of droplets or bulk to flow through its surface but can allow the passage of water vapors [6]. Waterproofness is measured in terms of hydrostatic pressure in mm. The waterproofing ratings also define their respective application products e.g., up till 10000 mm, light rain, average snow and pressure can be resisted while for values above 20000 mm, extreme rain, snow and high pressure can be withstood.

Electrospinning for nanofibrous membranes: Traditional membrane materials including polytetrafluoroethylene (PTFE) and thermoplastic polyurethane (TPU) when made via laminated strategy have certain disadvantages in comparison to each other such as cost and recycling for PTFE, and non-porosity resulting in low water permeability causing discomfort for TPU. In fact, combining both properties at the same time is very since protective ability and comfort have a negative relationship [7].

To overcome the shortcomings of the previous techniques, electrospinning has paved a new way in the formation of nanofibrous and porous membranes with high efficiency, optimized nano structures, and low weight. The technique itself is simple as it requires high voltage from a charged spinneret with polymeric solution that deposits the polymer onto a substrate such as liner fabric directly. With advanced systems of electrospinning, industrial scale continuous production of membranes laminated with fabrics is possible e.g., SS series of Inovenso. Ltd [8].

In recent years, a lot of effort has been put by researchers to improve the membrane properties such as vapor transmission simultaneously with hydrostatic pressure, avoiding fluorine-based materials that are hazardous to the environment, and producibility of highly hydrophobic resistant membranes. For this purpose, regulation on parameters is done such as processing parameters (voltage, deposition distance, injection flow rate, spinneret diameter), environmental parameters (relative humidity, temperature) and solution parameters (viscosity, conductivity, surface tension). By this, a balance is reachable between breathability and waterproofing ability [7].

Material types: In the last few years, many materials such as polyurethanes (PU), polyacrylonitrile (PAN), polyvinylidene fluoride (PVDF), polyether sulfone (PES), polyimide (PI), polypropylene (PP), polymethyl methacrylate (PMMA), Nylon 6 etc., have been investigated to produce optimal waterproof and breathable fabric materials. All these polymers have their unique abilities which contribute to the formation of the fabrics and in most cases, they are either combined among themselves or some other agents such as carbon nanotubes (CNTs), silicone dioxide (SiO2) and functional fluorine [7].

Products: The materials used when combined with the optimizations of electrospinning parameters leads to products from electrospinning such as Futurelight© by The North Face® [9] which utilizes PU elastic microporous membranes and was launched in 2019 as waterproof breathable fabrics for high exertion activities such as climbing. This brand has also been able to achieve PFC free final product and utilizes treated recycled fabrics and thus, are more environment friendly. Other waterproof breathable fabric brands include DryVent®, eVent®, GORE-TEX®, Polartec®- Neoshell® etc.

Applications: Generally, waterproof, and breathable fabrics find their applications, but are not limited, to following:

- Outdoor gear- hats, gloves, umbrellas, dry suits, tents etc.

- Construction- roofing materials due to lower weight, water resistance, UV resistance and acoustic insulation etc.

- Medical- hygiene, pillow covers, bed covers, surgical garments, wound dressings etc.

- Agriculture- tree shelters, packaging for product transportation, etc.

- Professional- protective military wear, functional heavy-duty wear, clean room clothing, fireman, farmer clothing etc.

- Sportswear- jackets, trousers, raincoats, swimwear, rainwear, skiwear, footwear, trekking shoes, camping boots etc.

Future directions: As described in this short article the different applications and possibility of products that can be made with waterproof breathable fabrics, a lot of work can be done on reaching an optimum level of fabric by choosing the correct material types such as polymers that can have a correct balance of breathability and waterproofness and simultaneously be comfortable enough to wear for longer periods. As mentioned earlier, the choice of material is very significant since the whole industry is moving towards PFC free products, which otherwise leave a negative impact on the environment and very hard to degrade. Finally, the choice of fabric formation is key for newer technologies where electrospinning is at the forefront of achieving high precision, optimally porous nanofibers at a very high production rate. Furthermore, the technique is flexible enough to incorporate and directly deposit on a substrate, novel fibers with multifunctionalities such as the liner fabric. Another edge of this technology would be the reduced post processing needed towards a final and finished product form.

References:

[1] UNEP/POPS/POPRC.14/6 (Meeting report)

[2] https://www.oecd.org/chemicalsafety/portal-perfluorinated-chemicals/

[3] https://www.hbm4eu.eu/hbm4eu-substances/per-polyfluorinated-compounds/

[5] Brennan, N. M., Evans, A. T., Fritz, M. K., Peak, S. A., & von Holst, H. E. (2021). Trends in the regulation of per-and polyfluoroalkyl substances (PFAS): a scoping review. International journal of environmental research and public health, 18(20), 10900.

[6] McCullough, E. A., Kwon, M., & Shim, H. (2003). A comparison of standard methods for measuring water vapour permeability of fabrics. Measurement Science and Technology, 14(8), 1402.

[7] Sheng, J., Zhao, J., Yu, X., Liu, L., Yu, J., & Ding, B. (2019). Electrospun nanofibers for waterproof and breathable clothing. In Electrospinning: Nanofabrication and applications (pp. 543-570). William Andrew Publishing.