OUR TECHNOLOGY

ELECTROSPINNING – ELECTROSPRAYING TECHNIQUES

The history of modern electrostatic spinning is the classic case of a scientific rediscovery. Indeed coupling electrical phenomena and fluids has been fascinating physicist for centuries, as reported in many studies and by the time started to call “electrospinning”

Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.

WHAT’S ELECTROSPINNING ?

Electrospinning is a fiber production method which uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.

Briefly; electrospinning uses an electrical charge to draw very fine (typically on the micro or nano scale or nanofiber) fibres from a liquid or polymer solution.

Nowadays basic electrospinning can be described as; The electrostatic force is applied to produce electrically charged jets out of viscoelastic polymer solutions, solvent is evaporated in time and nano-micro structures are obtained at the end of the process.

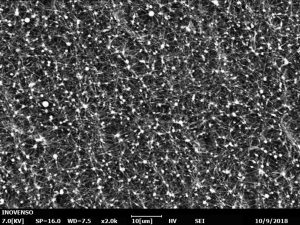

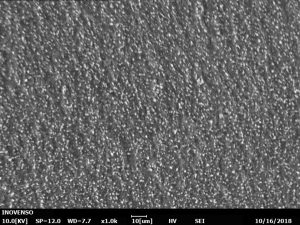

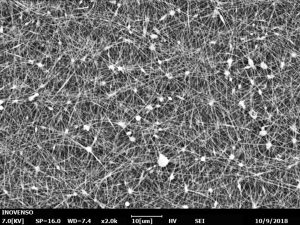

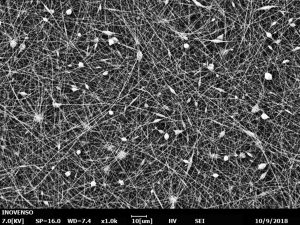

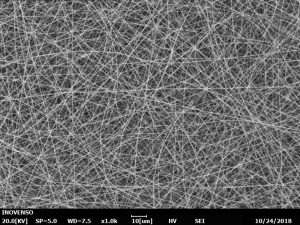

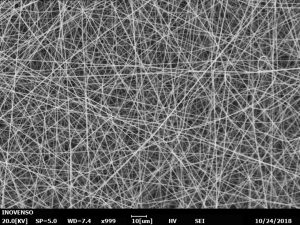

Structures of the resulting materials mainly depend on the concentration of the polymer solution. At lower solution concentrations spherical particles are observed. When it approaches to a critical value, bead-on-string morphologies are typically generated, i.e. electrospun fibers co-exist with particulates, and uniform fibers could be produced above the critical solution concentrations.

a b

c d

e f

Fig. SEM images of electrosprayed or electrospun PAN nanofiber with beads, bead-on-string and fibers structure obtained from solutions with different polymer concentration (w/v): (a) 2%, (b) 4%, (c) 6%, (d) 8%, (e) 10%, (f) 12% DMF/EA solutions.

In addition to their independent usages; it is also possible to obtain hybrid fiber-particle composite materials by combining these two methods together.

Nanofibers are one of the pioneering nanostructures due to their novel properties like extreme high surface area, low density, high pore volume, controllable mechanical properties as opposed to many other conventional bulk materials. They also represent a new generation of reinforcement for the fabrication of well-tailored unique nanocomposites. There are extensive variety and critical areas of applications of nanofibers such as healthcare, energy, catalysis, sensors, bioengineering and environmental technology to name a few.

Among many different processing techniques (like drawing, template synthesis, phase separation, self-assembly etc.); electrospinning offers a simple, straightforward and inexpensive process which enables producing homogeneous, uniform and continuous nanofibers from submicron diameters down to nanometer sizes. Furthermore; Electro-spinning technique allows the production of nanofibers from various materials e.g. organics and inorganics in different configurations and assemblies.

The Electrospinning process is initiated by application of high voltage to create an electric field between the droplet of the polymer solution and the collector. By increasing the electrostatic force; the spherical solution droplet elongates due to the accumulating charge on the surface of the drop and tends to form a conical shape. When the force reaches a certain limit that overcomes the surface tension of the drop, the polymer solution forms a jet moving towards the collector and the solvent evaporates during this motion. Dried nanofibers deposit on the collector and form an electrospun mesh.

Fig. Schematic diagram of the polymeric jet path from the needle to the collector (Angammana, C. J. (2011)).

Schematic illustration of the Taylor cone and jet formation: (A) the applied electric field creates surface charges in the polymeric solution; (B) increasing the voltage the drop is elongated; (C) when the voltage is higher than VC, the polymeric jet is formed and travels towards the collector due to the charge repulsion (Casasola, R. (2016)).

In order to obtain nanofibers with desired morphologies, there are three main branches of parameters that should be optimized before and during the process of electrospinning. These are solution properties, operation parameters and environmental conditions. The solution properties are given as molecular weight of the polymeric material, viscosity, conductivity and the surface tension of the polymeric solution. Moreover; the electric current has also an appreciable effect on the fiber morphology. The operating parameters are applied high voltage, flow rate and the distance between the tip of the spinneret and the collector. The solidification process during fiber formation with respect to evaporation rate of the solvent depends on the environmental conditions. Therefore, changing environmental conditions as like relative humidity and temperature, also makes a change on the characteristics of nanofibers.

| Solution Properties | Operation Parameters | Environmental Conditions |

| Molecular weight and solution viscosity Surface tension Solution conductivity Dielectric effect of solvent | Applied Voltage Feed Rate Tip to Collector Distance

| Relative Humidity Gas Atmosphere Temperature |